|

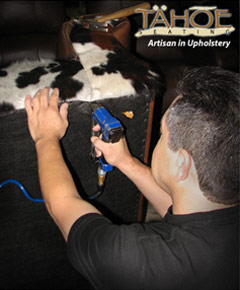

Tahoe Seating ConstructionAt Tahoe Seating, we use time tested, high quality methods to manufacture your seating. For frames, we use selected kiln-dried hardwoods that are cut and assembled by hand using nails, bolts and industry wood. All cross member supports are comprised of 1" thick hardwood. A corner blocking technique is used to provide extra support in the seats' stress points. The feet screw into hardwood supports, with anchored receiving bolts. In our seat suspension, we use a European elastic webbing technique that provides for a more uniform distribution of weight, and has been known to four to five times longer than springs or coils. Cushions contain high quality polyurethane foam ranging from 1.8 - 2.3 lb. densities. The polyurethane foam is wrapped with a Dacron fiber, which ensures that cushions retain their shape, and prevents the upholstery from creeping and slipping. Tahoe Seating uses foam to wrap our wood frames to prevent and insure your covering (leather or material) will never contact the wood frames. This prevents your covering from ever touching the wood frame that could cause wear on the underside of the covering. Lastly, each piece of furniture is handcrafted and personally inspected by the owner, who has over 25 years of high-end furniture manufacturing experience, to ensure the highest quality product.

|